Dangerous goods disposal

Demilitarisation

Demilitarisation is an internationally accepted component of the defence industry and is required by all countries to dispose of time expired, faulty and redundant ammunition.

Many countries are not subject to environmental regulation and disposal often occurs by open burn/open detonation (OB/OD). For nearly three decades Vertrex has championed the replacement of OB/OD with environmentally responsible processes through acceptable methods of breakdown of ammunition into components, and the initiation and emission treatment of the chemical compounds.

Vertrex offers specialised environmentally acceptable solutions for large-scale ammunition disposal and destruction of other hazardous goods. We have capacity for the demilitarisation of small arms ammunition – such as 9mm, 5.56mm and 7.62mm – through to various medium calibres and up to specialist natures in 155mm artillery.

Vertrex places the highest importance on developing techniques that enable the company to carry out this work in a safe and environmentally responsible manner.

View dangerous goods

disposal projects

Disposal of hazardous goods and pyrotechnics

Vertrex is licenced and qualified to transport, receive and treat products – including marine flares, airbag inflators and other hazardous products – by thermal destruction and non-thermal treatment.

These disposal activities are conducted under the EPA Waste Premises licence 11947 and EPA waste transport licence NSW EPA licence 11920.

Vertrex uses the online waste tracking system developed by the NSW EPA, which automatically informs the client, the receiving site and EPA authorities of waste transport. This enables the Company to receive and dispose of products through environmentally acceptable, safe, cost-effective and capable solutions.

Hazardous goods handling solutions

Vertrex has the infrastructure and expertise to develop solutions for unique challenges associated with handling dangerous and hazardous goods on a project-by-project basis.

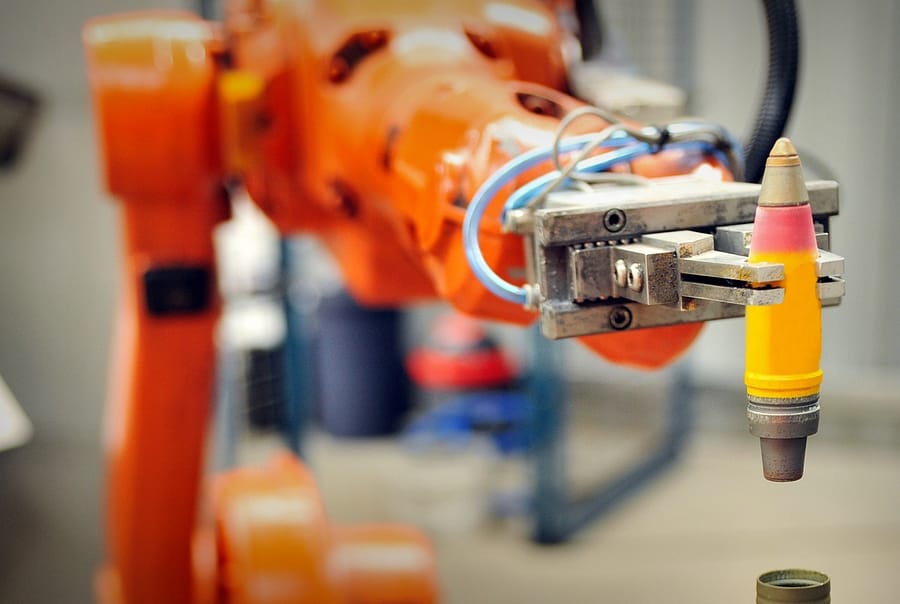

Remote, robotic and automated processing of dangerous goods for disposal is prioritised to mitigate risks, especially those relating to munitions disposal.

Where required, systems are set up within protective blast-proof walls, and operators control the dismantling of dangerous goods remotely. Gantries and conveyor systems are used to mitigate risks associated with manual handling. Detailed work instructions are developed by technicians and subject matter experts to use in training, ensuring all safety protocols and risk control measures are communicated to operators.

Safety is always the most important factor for all hazardous goods handling solutions Vetrex develops and all activities are conducted strictly within the guidelines set by Defence Explosive Licencing and SafeWork NSW.

Recycling of plastics, metal and timber

Vertrex recovers, reuses and recycles all materials where possible.

We strive to minimise waste released to landfill or other offsite treatment facilities.

Recovered products are separated into materials that can be reused for their current purpose or recyclables that can be reprocessed into feedstock for new material.