Equipment

Thermal

treatment line

Vertrex operates four thermal destruction furnaces, which have pollution control equipment fitted.

Each have afterburners that can operate up to 980ºC with a minimum two-second residence time, allowing for a high degree of thermal decomposition of partially combusted products (e.g. phenols, aromatic hydrocarbons, aldehydes, carbon monoxide and carbon particulate).

Non-thermal

treatment line

Vertrex operates a wet emission treatment line offering the highest commercially available particulate scrubbing efficiency for dense concentrations of sub-micron particulate.

The system consists of a three-stage scrubbing process:

- Water deluge spray tower

- High-pressure flooded venturi

- Cyclonic wastewater separator

A high-pressure fan provides the required pressure drop across the scrubbing system, while also providing adequate extraction to capture emissions as they are generated.

Ammunition

breakdown

equipment

Vertrex specialises in the disposal of ammunition of all sizes, with specialist disposal options available upon request, subject to a feasibility and operational risk review.

Vertrex has a range of air operated approved vices and dismantling equipment, which is regularly earth checked and tested.

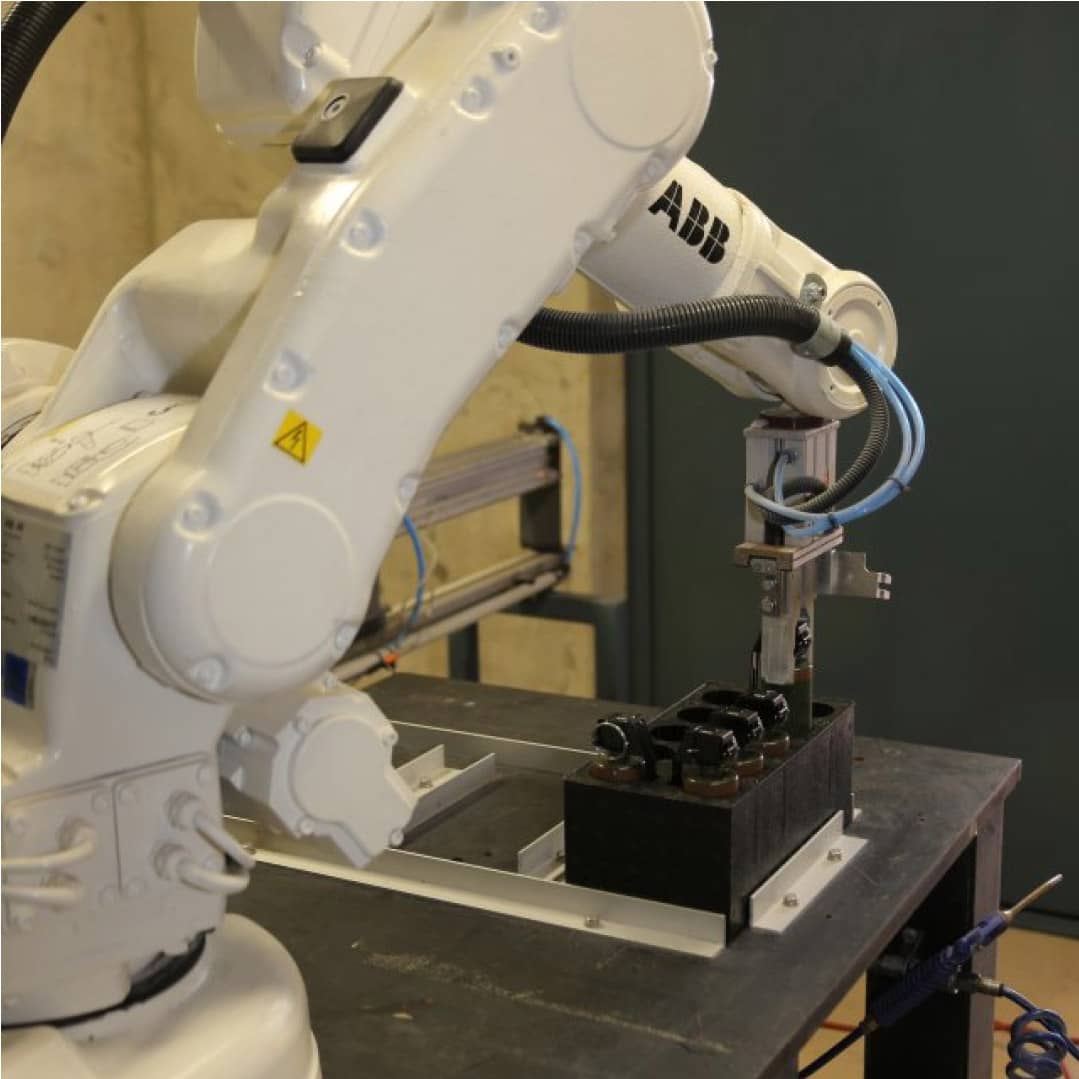

We use cutting-edge six-axis industrial robots paired with the latest generation programmable logic control systems across our facilities for the handling of munitions and explosive ordnance.

We have several IB 140s for the handling of medium calibre ammunition. Tasks can include loading into projectile pulling processes, delivering to noise attenuating initiating chambers, defuzing equipment, or other disassembly processes.

We also use an IRB 6600 for handling explosive ordnance, while our UR 10 is used for loading fuzed explosive ordnance and unloading components after disassembly is complete.

Spray paint line

equipment

Vertrex offers a range of undercoating and top coating paint systems along with customised stencilling.

Our main spray line in Wangaratta, Victoria, is used for priming and painting steel and timber packaging to meet military specifications.

During peak demand, and when additional box preparation and storage is required, we are able to utilise a secondary spray line at our facility in Oaklands, NSW.

Packaging marking

facilities

Vertrex has a range of stencilling and marking equipment, with the ability to manufacture unique stencils.

We also offer barcoding product-tracking solutions.